Stop Paying More for the

Same Workholding.

The Full Grip delivers premium CNC workholding without the industry’s usual markups, middlemen, or mystery pricing.

TOP CATEGORIES

-

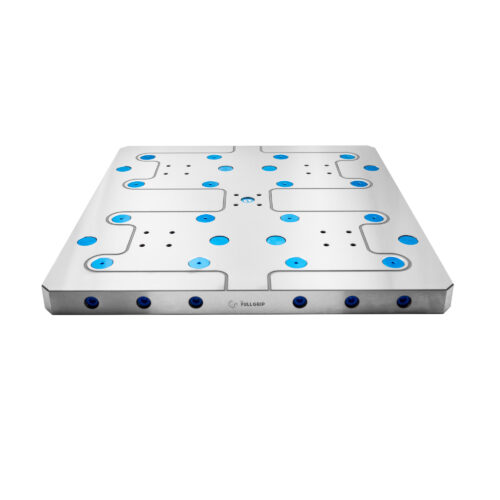

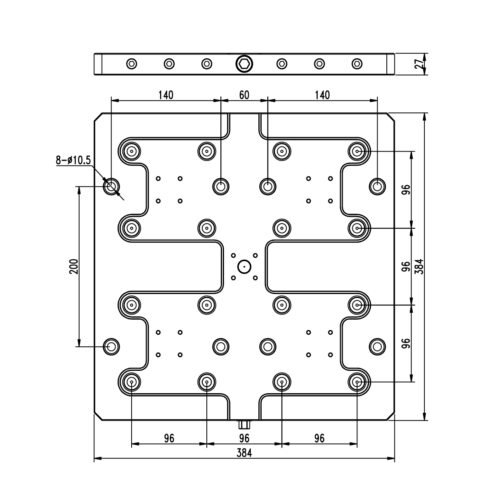

Combo Plates (3)

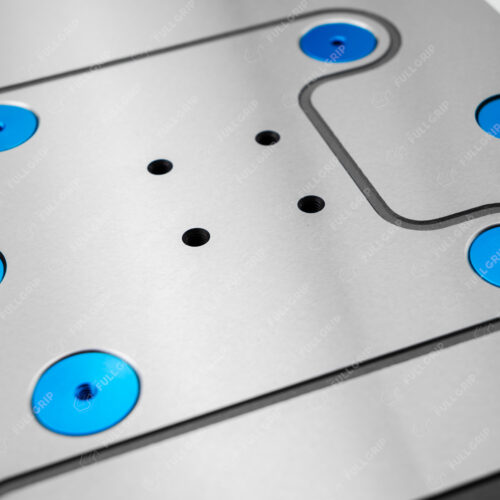

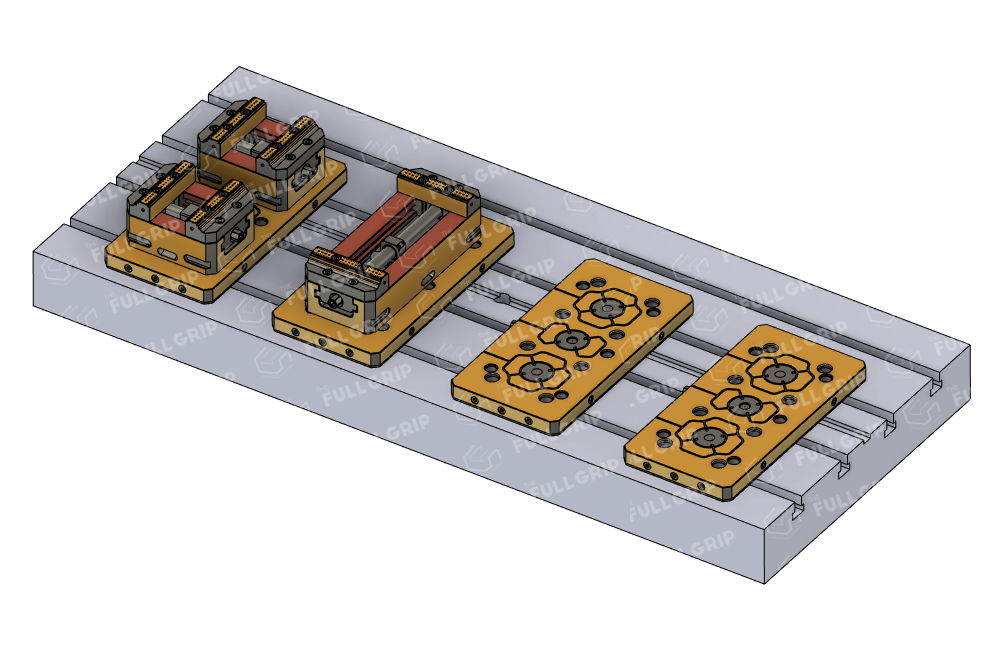

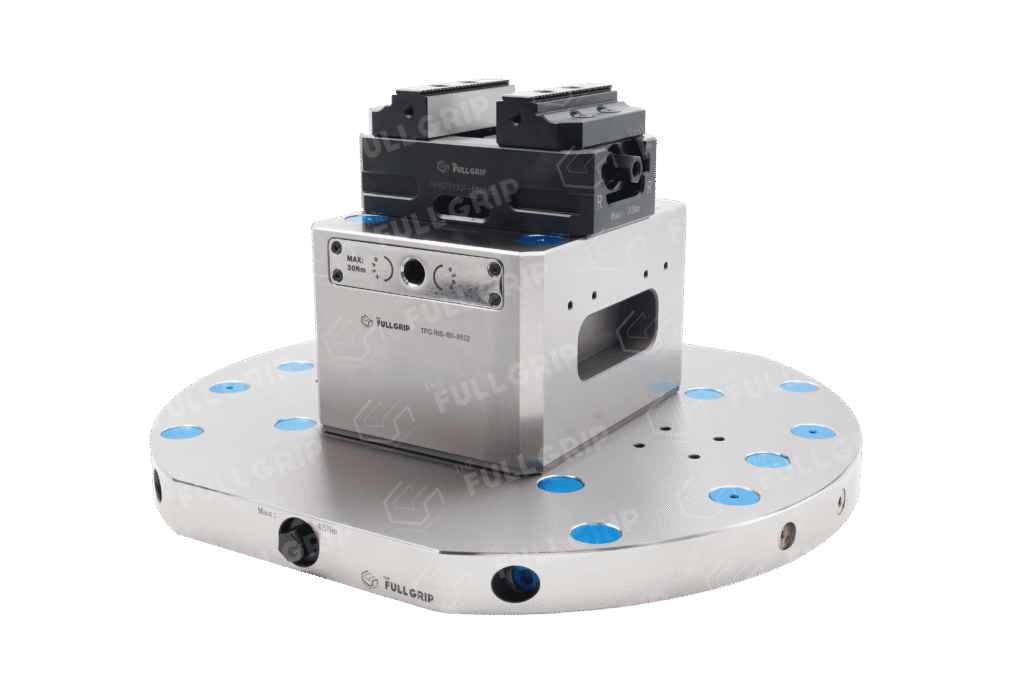

Combo plates feature both 52 mm and 96 mm grid systems in a single zero-point setup, making them compatible with all The full Grip vices. This combined grid layout helps speed up changeovers and improve efficiency. Available in square, rectangular and round formats. -

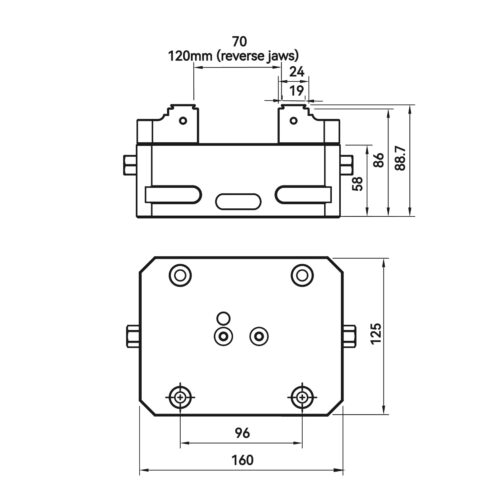

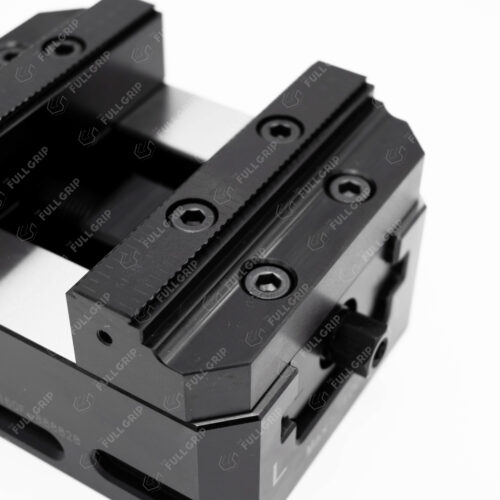

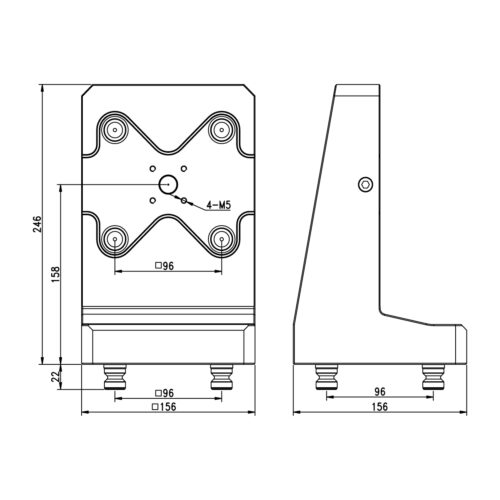

Self-centering (6)

High precision, wide clamping range, lightweight design, and flexible operation. -

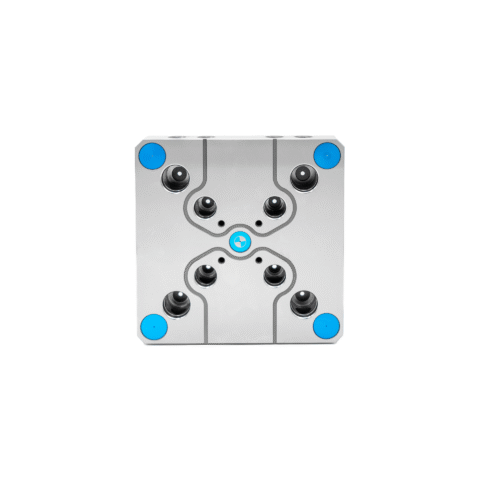

Zero Point Plates (9)

Zero-point plates come in almost 50 variations, featuring two grid sizes: 52 mm and 96 mm. They are adaptable to a wide range of applications and machine tables, suitable for use in both vertical and horizontal machining centres, as well as 3-axis and 5-axis tables, CNC rotary tables, and tombstones.

YOU’RE PAYING FOR PROBLEMS YOU DON’T NEED.

LET’S FIX THAT.

Industry Pricing Markups

Most workholding brands bake sales reps, retail networks, and distribution layers into their price tag. You end up paying for the bloat, not the engineering.

Why should a vice cost thousands just because it passed through three layers of people who never stepped foot in your shop?

TFG keeps things brutally simple: a lean team, direct-to-you supply, transparent pricing, and precision gear built for serious machinists.

“Will This Actually Fit My Machine?”

Specs are unclear, CAD files aren’t available, and you don’t know whether that plate or vice will actually fit your setup.

Winging it shouldn’t be part of your machining workflow. Time is money, and wrong-fit workholding kills both.

Every The Full Grip product comes with downloadable CAD data so you can test-fit your setup before you buy. No surprises.

Slow Changeovers & Lost Spindle Time

Workholding inefficiencies drag down your spindle hours and bottleneck production.

If you’re still re-indicating fixtures every time you switch parts, you’re burning money with every minute of downtime.

Our zero point systems and self-centering vices are built for speed, accuracy, and repeatability, giving you faster changeovers and more cutting time.

EVERY JOB HAS A “THAT WON’T FIT” MOMENT

Off-the-shelf fixtures don’t always match the part, table, or machine.

You shouldn’t have to redesign your workflow just to make your workholding behave.

We build custom plates, tombstones, risers, fixtures, and adapters to suit your exact specs. If you can draw it, we can make it.

REAL SHOPS. REAL SETUPS. REAL RESULTS.

Machinists across Australia and beyond use TFG gear to save time, simplify setups, and cut costs without compromising precision.

The Full Grip dramatically improved our setup time and ensures unparalleled part-to-part consistency, even on complex geometries. It delivers the solid, reliable clamping force essential for achieving micro-tolerances.

We saw an immediate reduction in chatter and vibration thanks to the rock-solid grip of this workholding solution. Investing in The Full Grip has directly translated into higher surface finishes and fewer scrapped parts.

This system is a true time-saver; changing fixtures with The Full Grip is fast and seamless, maximizing our machine uptime. It is robust enough to handle high-feed milling while remaining simple enough for quick-turn jobs.

FEATURED

PRODUCTS

WHY CHOOSE THE FULL GRIP

Precision workholding without the industry nonsense.

Transparent Pricing

No quotes-only pages. No “talk to a rep”. Every price is listed upfront.

Lean, Direct Supply Chain

No distributors, no wholesalers, no add-on fees. Just great gear at honest pricing.

Engineered for Compatibility

Everything follows industry-standard 52 mm and 96 mm systems. Mix and match with what you already own.

Built for Machinists

Every product is tested, measured, refined, and used by real CNC operators - not marketing departments.

Custom Solutions Available

From zero point plates to tombstones to one-off fixtures, we can build it to your drawing.

FREQUENTLY

ASKED

QUESTIONS

Are your workholding products compatible with other 52/96 manufacturers?

Yes. All TFG workholding is designed around industry-standard 52 mm and 96 mm platforms, making it compatible with most major modular systems.

Do you provide CAD data for downloading?

Yes. We offer CAD models for major products so you can test-fit them in your setup before buying.

How do I get a quote for these products?

All products on our website are available by quote.

Simply submit a request through the product page or our contact form, and we’ll get back to you with pricing and the most economical shipping rate for your location.

For custom workholding, simply submit your drawings or requirements through our contact form and we’ll send a tailored quote.

Simply submit a request through the product page or our contact form, and we’ll get back to you with pricing and the most economical shipping rate for your location.

For custom workholding, simply submit your drawings or requirements through our contact form and we’ll send a tailored quote.

READY TO UPGRADE YOUR WORKHOLDING?

Whether you’re looking for precision vices, faster changeovers, or a custom-built solution for a tricky job, we’ll help you get the setup that works for you.